Research Institute

RESEARCH

Research and Development Department

Research and Development System of Kawai Pharmaceutical Cosmetics.

Quality, Speed, and Safety are the Core Competencies of the Company

The company has a professional R&D team and the latest equipment, not only able to develop cosmetics that meet customer needs but also achieving quality standards that exceed customer expectations.

Only professional researchers who are familiar with the composition structure of cosmetics, combined with various advanced equipment, and able to prove their effectiveness and safety, can create "high-quality cosmetics".

Currently, Kawai Pharmaceutical's laboratory has a database of over 10,000 prescriptions and a complete set of equipment necessary for prototype production of cosmetics. Professional R&D personnel are actively working every day to develop various high-quality cosmetics that meet customer needs.

Rich Experience and Achievements

The Company Has Accumulated Over 10,000 Prescriptions and Patents

The production workshop requires multiple inspections throughout the entire cosmetics manufacturing process.

Since cosmetics come into direct contact with the skin, thorough hygiene management is extremely important.

Kawai Pharmaceutical's motto is "No excessive hygiene management." While ensuring safety and high quality, the daily diligent efforts of all staff are the main reason we have earned the trust of over 850 customers.

Fully Equipped

Research Equipment

The laboratory is equipped with various advanced equipment to strive for creating high-quality products that exceed customer expectations. The main equipment is as follows:

・Wet High-Pressure Atomizer

Applies pressure to emulsions and the like to form nanoparticles.

The maximum pressure that can be applied is 200 MPa,

and water becomes hot after applying pressure.

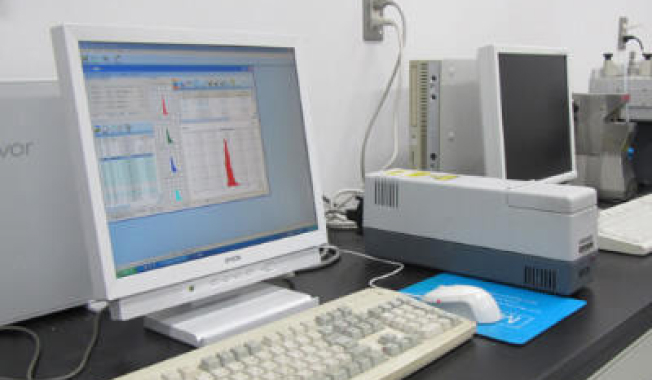

・Particle Size Distribution Meter

A device for measuring particle sizes. During the production process, it is necessary to specially measure nano-sized particles. Using this equipment, we can verify that these particles are indeed nano-sized.

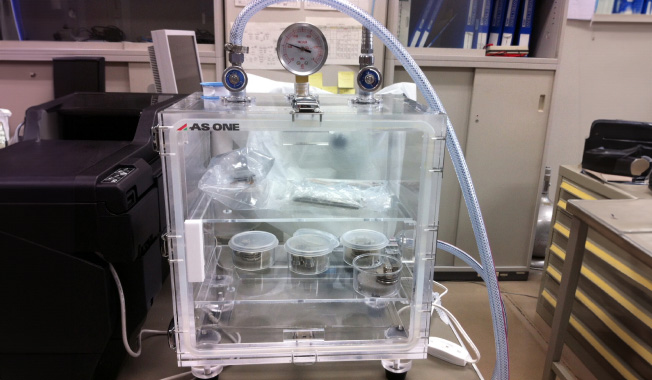

・Vacuum Dryer

This equipment can create a vacuum inside the machine and check if the container is leaking. We not only perform necessary safety checks on the contents of the cosmetics but also perform safety checks after placing them in the containers.

・Incubator

This equipment can store completed prototypes and check if they can withstand temperature changes. For example, it's like a hot/cold storage freezer that stores all completed prototypes and benchmark products provided by customers and checks their stability. Both short-term tests (3 days) and long-term tests (6 months) can be conducted using this equipment.

Highly Specialized Researchers

Cosmetics Manufacturing Specialty

The company has various specialized researchers who dedicate themselves with enthusiasm every day, continuously striving to develop high-quality cosmetics that exceed customer expectations. The research team can perceive subtle changes that machines cannot measure, using their professional knowledge and experience to turn customers' dreams into reality. The company aims to "provide unique cosmetics," maximizing product advantages while ensuring their efficacy.